发布时间:01-24

Principle: flame retardant magnesium hydroxide belongs to add flame retardant agent, thermal decomposition releases moisture, absorb a large amount of heat at the same time, can reduce the temperature of the material surface, making slow the rate of polymer degradation, then small molecule fuel production is reduced. Release of the surface of the water dilutes the oxygen, make the burning harder.

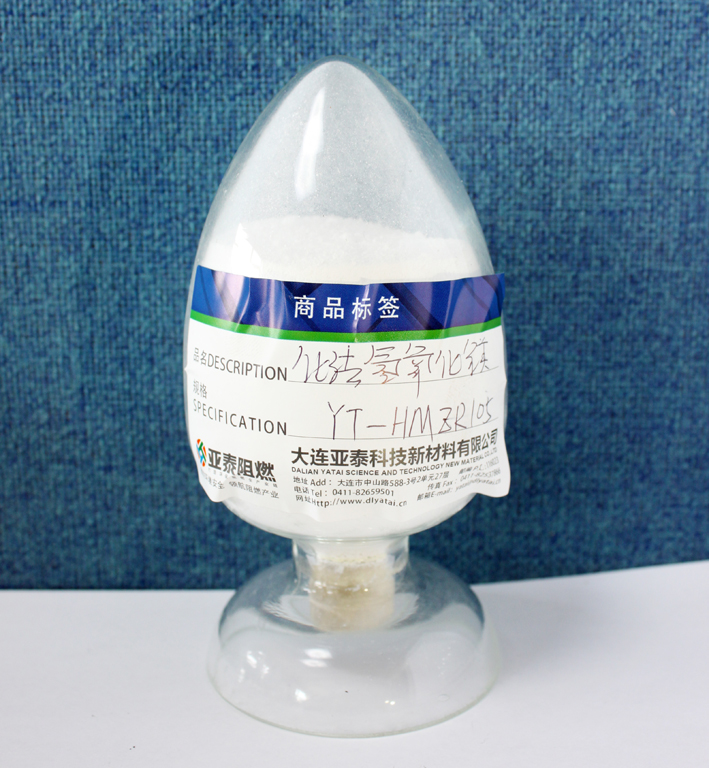

1 the characteristics of the magnesium hydroxide flame retardant

Magnesium hydroxide Mg (OH) 2, the white solid powder, insoluble in alkaline substance, thermal decomposition of magnesium oxide and water, and began to decompose when heated to 340 ℃, 430 ℃ when decompose fastest, completely break down to 490 ℃. Magnesium hydroxide crystal, belong to 2 valence metal hydrate crystal structure is layered CdI2 type, form continuous hexagonal, magnesium 2 + and OH - layer overlap each other, each magnesium ions are 6 hydroxyl ions cooperate to form Mg (OH) 6 octahedron. Standard conditions: Mg (OH) 2 (s) of MgO style (s) + H2O (g) delta H = 81.02 kJ/mol, same as inorganic flame retardants,

Compared with magnesium hydroxide and aluminum hydroxide has many advantages:

1) aluminum hydroxide thermal decomposition temperature is 245 ~ 320 ℃, compared with magnesium hydroxide decomposition temperature 340 ~ 490 ℃, the effective use of low range, suitable for use in a relatively low processing temperature such as ABS resin, acrylic resin and epoxy resin, etc. Aluminum hydroxide due to the low decomposition temperature, some of the water of crystallization in material processing has decomposition, easy to make the products more bubble, porous, its flame retardant effect also fall. And magnesium hydroxide can be add material makes higher processing temperature, extrusion speed and shorten the molding time. Decomposition can be bigger than aluminium hydroxide and magnesium hydroxide, high heat capacity, able to inhale more heat and flame retardant effect better [2].

(2) magnesium hydroxide granularity is smaller than aluminum hydroxide, less wear of materials processing equipment, to extend the service life of equipment.

(3) magnesium hydroxide of the effect of smoke is better than aluminum hydroxide, can counteract toxic gases such as sulfur dioxide, carbon dioxide from the burning of polymer, etc.

(4) the abundant raw materials, easy, contains large amounts of magnesium salt water resources, as well as magnesite as magnesite, dolomite and brucite, etc.

2 the mechanism of the magnesium hydroxide flame retardant

Flame retardant magnesium hydroxide belongs to add type, thermal decomposition releases moisture, absorb a large amount of heat at the same time, can reduce the temperature of the material surface, making slow the rate of polymer degradation, then small molecule fuel production is reduced. Release of the surface of the water dilutes the oxygen, make the burning harder. Magnesium hydroxide in the surface of the material form carbonization layer, prevent the entry of oxygen and heat, decomposition of magnesium oxide and magnesium hydroxide is high-grade refractory material, so when the combustion source, the fire will automatically stop, have the effect of flame retardant. Because of the magnesium hydroxide flame retardant role mainly in polymer degradation area, reduce the production of fuel, but very little effect on mixing zone, little impact of fuel combustion, smoke less, and magnesium hydroxide can dilute and absorb smoke, so magnesium hydroxide has the effect of smoke.

3 the preparation of magnesium hydroxide

3.1 the characteristics of magnesium hydroxide flame retardant requirement for common magnesium hydroxide of amorphous or hexagonal crystal, specific surface area is large, grain easy two gathered, strong polarity, fill in resin, plastic and other bad dispersion, and easy to make material mechanical strength decreased obviously, especially the impact strength, so the ordinary is not suitable for filling with flame retardant type magnesium hydroxide. Magnesium hydroxide used as flame retardants, must pass special processing and surface modification, with specific crystal shape.

General requirements:

1) crystal shape of fiber shape, it can increase the elongation and the flexural strength of the material.

(2) must be of high purity, the higher the purity, the better flame retardant effect.

(3) particles as small as possible experiments show fill to nanometer magnesium hydroxide as fire retardant material, various aspects including the flame retardant performance effect, smoke abatement and mechanical properties of magnesium hydroxide is superior than microns.

(4) on the surface of low polarity, ordinary magnesium hydroxide is due to the high surface polarity and micro internal stress is large, as fire retardant filling into the material influence the mechanical properties of the materials. When surface polarity is low, particle gathering clouds reduce, dispersibility and compatibility in the material increases, the impact on the materials mechanical properties reduced [4]. So use the appropriate dosage of surface active agent and surface processing, to improve the compatibility with polymers.

5. Specific surface area is less than 20 m2 / g, distorted values in the (101) orientation is less than 3.0 x 0.001, (101) orientation of the crystal size is larger than 80 nm, only have more characteristic of magnesium hydroxide and material better compatibility.

3.2 the surface treatment of the surface modification of magnesium hydroxide magnesium hydroxide can use the surfactant and the surface of magnesium hydroxide particles up chemical reaction, also available surfactant coated on the surface of a magnesium hydroxide particles. Both change particle surface state, make particles to create new performance, and material compatibility is better, prevent the lower material mechanical performance [5, 6]. Commonly used magnesium hydroxide surface modification agent is a coupling agent, sodium stearate, sodium oleate and titanate ester, the dosage of 1% ~ 3%.